Liquid manure to solid gold

Bob Midden, students work to make environmental concern a profitable option

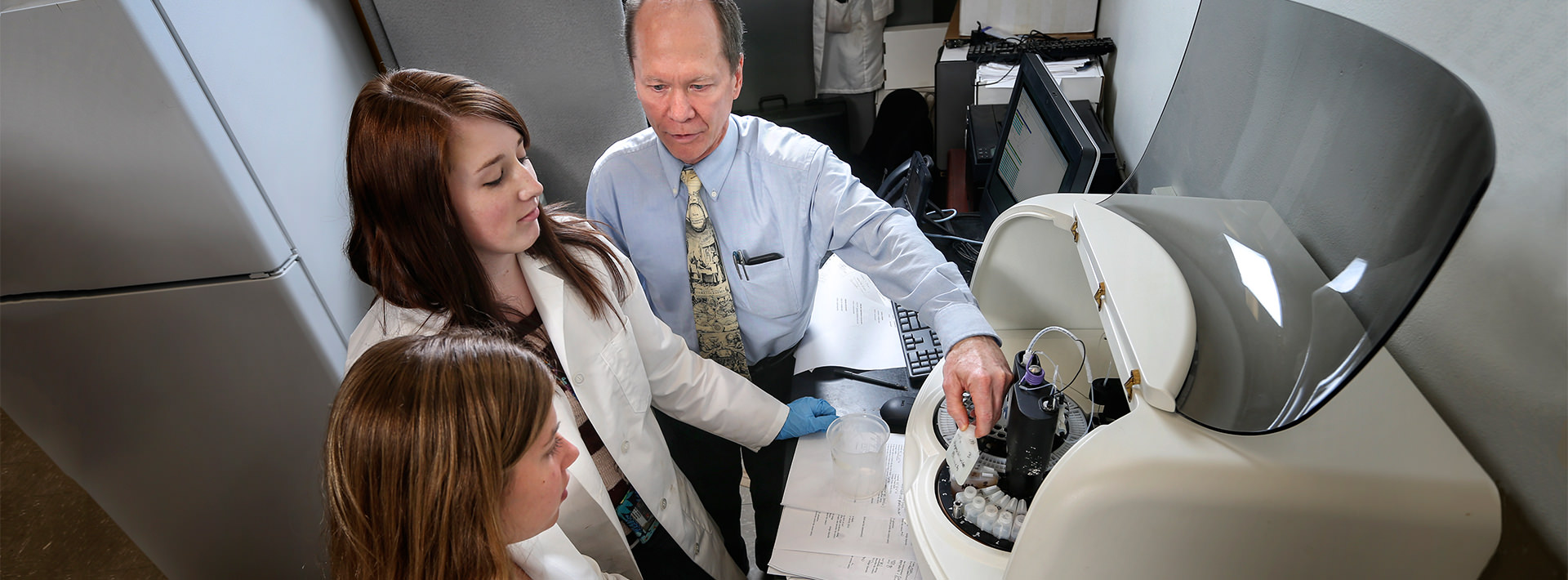

Robert Midden, chemistry, analyzes water samples with (center) Jennifer Marshall, a freshman environmental science major, and Rebecca Shroka, a sophomore AYA chemistry and physics major, using an instrument called the discrete chemical analyzer, which determines the levels of phosphate, nitrate and ammonia in water samples.

By: Jen Sobolewski

Large-scale dairy farms have been a divisive issue in Ohio since they started popping up in rural areas across the state. One of the main concerns is the large amount of diluted manure these farms produce. But what if the nutrients that make manure so good for the soil could be removed from this liquid and sold as a low-cost, high-yield fertilizer? It’s a question that Dr. Bob Midden, chemistry, and six of his undergraduate students are trying to answer.

The village of Ottawa in Putnam County approached Midden in December 2012 to see if he’d be interested in working with them in the development of this process. Putnam County is home to a number of these large-scale farms.

“Crop fertilizer is one of the most expensive parts of growing crops, so that represents value, but because of the high water content it is expensive to transport that material very far relative to its value,” Midden explained. “If you apply more nutrients to the land than can be absorbed by the crops, when it rains or snows and ice melts, it can be washed into the waterways.”

If most of the water is eliminated from the dilute manure produced by large-scale farms, Midden says what is left is material that is much lighter and cheaper to move. His team has developed a process that binds the nutrients in the manure together so it can be filtered out as a solid.

The science behind it is relatively simple. First, lime is added to the liquid manure, which raises the ph. level and kills off the microorganisms. Next, a polymer is added, which grabs the “fertilizer” in the manure — phosphate, nitrate and nitrite — essentially pulling all the solids out of the water. Then the solids are filtered out. If the treatment process works as well as Midden hopes, the water can simply be released with no harm to the environment.

He said that occasionally they will have to add ferric chloride or alum to the liquid to enhance the process, but that they are working to eliminate that step. “We want to find a polymer and conditions that will achieve the results we want without alum or ferric chloride. They require additional equipment and storage, which increases the cost, and ferric chloride is a somewhat caustic material that’s a little hazardous to handle.”

Midden’s team then takes plastic tubes filled with soil, mixes the solid material in the top and simulates rain. After a certain number of simulations they test the soil to see how far the nutrients traveled. They look at how rapidly the nutrients are released and how much they move through the soil. “Ideally you want to see the nutrients eventually released at a slow rate closer to the rate that the crops will absorb.”

While their preliminary results are promising, Midden said they’ve only done testing and development in the lab. He is preparing for pilot tests at the Ohio State Agriculture Research Station in southern Wood County. Additional tests will involve growing crops and a full-sized field test to see which polymers work the best in matching the absorption in crops, and trapping the maximum amount of nutrients from the manure and then releasing the maximum amount in the soil.

“I never expected to be involved with research my freshman year...It’s cool to be in a lab, talk about this with my family and do hands-on things.”The project has received considerable interest from various state agencies and organizations as well as some state legislators. Midden is hoping that interest will translate into grant money to fund the next step in the research. That includes getting manure samples from multiple dairy farms for testing.

“We need to make sure the process works consistently and reliably across all different conditions and materials even processed in different conditions. Once we have a viable process we can start to process manure at the Ottawa wastewater treatment plant.”

In a stroke of luck, Ottawa has one wastewater treatment unit sitting idle and is willing to let Midden and his team use it to process manure on a commercial scale when they are ready.

“One aspect of our work is aimed at minimizing the cost of this treatment process. If we can keep the cost low, this method of dealing with the manure could be economically competitive with other methods of simply applying it or transporting it elsewhere,” said Midden. “In fact, one hope is that we could produce material so valuable it could be sold and generate more income than the process even costs. So it could be a profitable way to deal with this and thereby provide a strong financial incentive to use this alternative method that would greatly reduce the environmental impact. So that’s what we’re striving for.”

Midden also has a strong educational component to this project. He currently has six undergraduate students working in the lab; the majority of them are first-year students. “I think the best way to learn science is to get involved in something like this, and what better time to do that then in your first year,” he said.

During one of their progress meetings they discussed getting a new runoff sample during the first major thaw and troubles they were having in the lab with getting the material to filter properly. Midden offered his suggestions and also challenged the students to help them solve their problems.

“I never expected to be involved with research my freshman year,” said Kimberly Lentz, who is from Mentor and majoring in adolescent to young adult math education. “It’s cool to be in a lab, talk about this with my family and do hands-on things.”

“I never thought I’d be working with manure,” exclaimed Sarah Jindra, a junior from Brunswick majoring in chemistry.

Devoney Miller, a first-year student from Westerville majoring in middle childhood education, was surprised when she first encountered a large-scale dairy farm. “It was interesting to see how they feed the manure down these tubes and across the street, through the water. I was really amazed by the big production in putting the manure on the ground.”

Miller also said she’s excited to work on a project where her work could have a major impact on the region. “I wanted to do something where my results would go someplace bigger than just Bowling Green.”

Updated: 12/02/2017 12:50AM