Nationally recognized for student experience

The Wall Street Journal

Bachelor of Science (B.S.)

Mechanical and Manufacturing Engineering

Mechanical and manufacturing engineering is a career for creative thinkers with an affinity for technology and a knack for leadership.

The Bachelor of Science in mechanical and manufacturing engineering (MME) program at BGSU reflects our future-focused vision. Graduates can step directly from the commencement stage into a high-powered career.

Design and develop the parts, processes and systems of our world. Revolutionize the machines used in everything from medicine to space exploration. Discover solutions that are faster, smarter, safer and eco-friendlier. Do it all in northwest Ohio, the epicenter of America’s manufacturing heartland.

Why study mechanical and manufacturing engineering at BGSU in Ohio?

- Make a tangible difference. Translate theoretical engineering ideas into better products and processes used in everyday life.

- Small class sizes. Our low ratio of students to instructors maximizes the 1:1 time you need to be successful.

- Learn from the best. All engineering courses and labs are taught by Ph.D.-level faculty with valuable industry experience, giving students both strong technical skills and real-world insight. BGSU engineering faculty are also actively involved in advanced research alongside highly-respected industry partners.

- Co-op connections. Gain unparalleled real-world experience through our required cooperative education (co-op) program. BGSU has one of only a dozen accredited co-op programs in the U.S., offering 3,000+ employer connections.

- Invaluable networking opportunities. BGSU offers many ways to make professional connections through organizations such as the Society of Manufacturing Engineers (SME), the Society of Automotive Engineers (SAE), the American Society for Quality (ASQ) and The American Society of Mechanical Engineers (ASME).

U.S. Department of Education data shows 100% of engineering degree graduates recoup their education costs within 5 years.

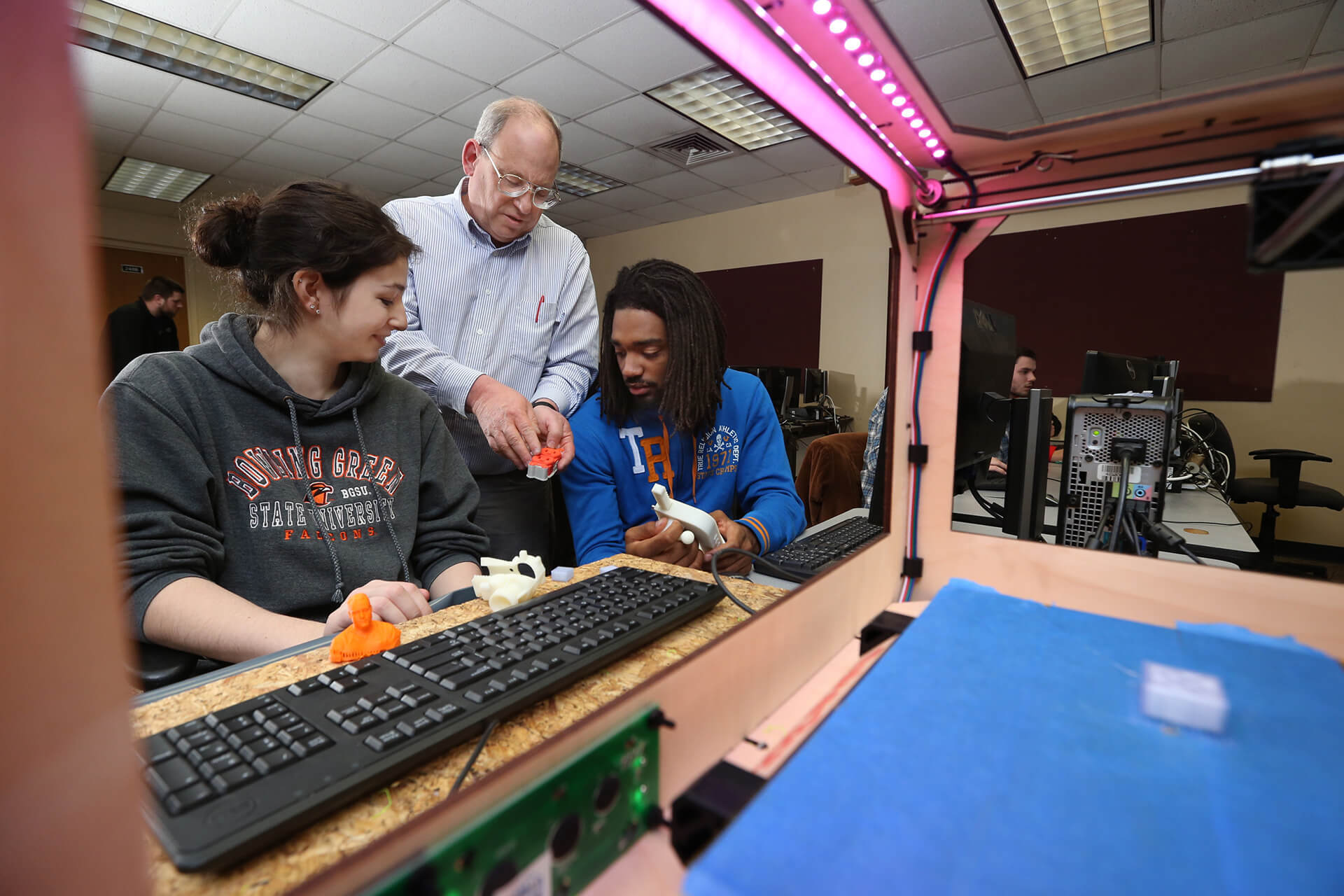

Mechanical and manufacturing engineering labs for next-level learning

Theoretical knowledge only gets you so far in engineering. BGSU has more than a dozen state-of-the-art laboratories. Each is designed to maximize opportunities for intensive, hands-on training, collaboration and research.

About 80% of our engineering courses include lab experiences. Lab work allows you to dive right into things like prototyping, manufacturing, metrology, robotics and material testing.

Laboratories in regular use by MME majors include:

- Metals and machining, GD&T

- Advanced manufacturing

- Thermodynamics/Heat

- CAD, CAM, simulation

- AI and VR lab

All this is in addition to 22,000 square feet of support spaces – a Hazmat room, innovation center, conference rooms, maker space, tech store, project rooms and more.

BGSU is committed to continuous investment in cutting-edge equipment, ensuring engineering students are ready for real-world roles the day they graduate.

#1 public university in Ohio for career prep

The Wall Street Journal

Career - what can you do with a mechanical and manufacturing engineering degree?

A mechanical and manufacturing engineering degree from BGSU combines knowledge and experience that aligns directly with job market demand. Mechanical and manufacturing engineering graduates aren’t machine operators or assembly-line workers. They’re highly skilled engineers who pair teamwork and technical skills to solve complex problems.

Jobs for MME majors run the gamut.

- Team up to prototype, test and refine new product designs as a product development engineer or process engineer.

- Serve as a link between engineering and production teams as a manufacturing engineer.

- Combine your tech and communication skills to negotiate high-end deals as a sales engineer.

BGSU MME graduates can expect high demand and competitive pay for their skills no matter which field they enter.

Career paths

- Mechanical engineer

- Manufacturing engineer

- Product designer

- Biomedical engineer

- Design engineer

- Process engineer

- Quality engineer

- Plant manager

Quick Facts from the Bureau of Labor Statistics

Curriculum

The mechanical and manufacturing engineering curriculum at BGSU is intensive and comprehensive. It combines classroom instruction with hands-on experience in the areas of design, manufacturing and implementation.

The program consists of 122 credit hours:

- 24 credit hours of general engineering

- 39 credit hours in mechanical and manufacturing core courses

- 6 hours of technical electives

- 6 credit hours of business courses

You also must complete two semester-long, paid co-ops and a senior capstone project.

Sample courses

- Computer Aided Manufacturing (CAM)

- Advanced Manufacturing

- Manufacturing Processes

- Manufacturing Design and Operations

- Engineering Materials

- Advanced Modeling and Simulation

- Statics and Dynamics

- Heat Transfer

- Fluid Mechanics

- Thermodynamics

- Numerical Methods

#1 university in Ohio – big or small, public or private – students would choose again

The Wall Street Journal

News

The mechanical and manufacturing engineering program is part of the School of Engineering in the BGSU College of Engineering and Innovation.

Accreditation

Bowling Green State University [BGSU] is accredited by the Higher Learning Commission. BGSU has been accredited by the Higher Learning Commission since 01/01/1916. The most recent reaffirmation of accreditation was received in 2022-2023, with our next reaffirmation of accreditation scheduled for 2032-2033. Questions should be directed to the Office of Institutional Effectiveness.

Request Information

Updated: 02/06/2026 04:20PM