Facilities

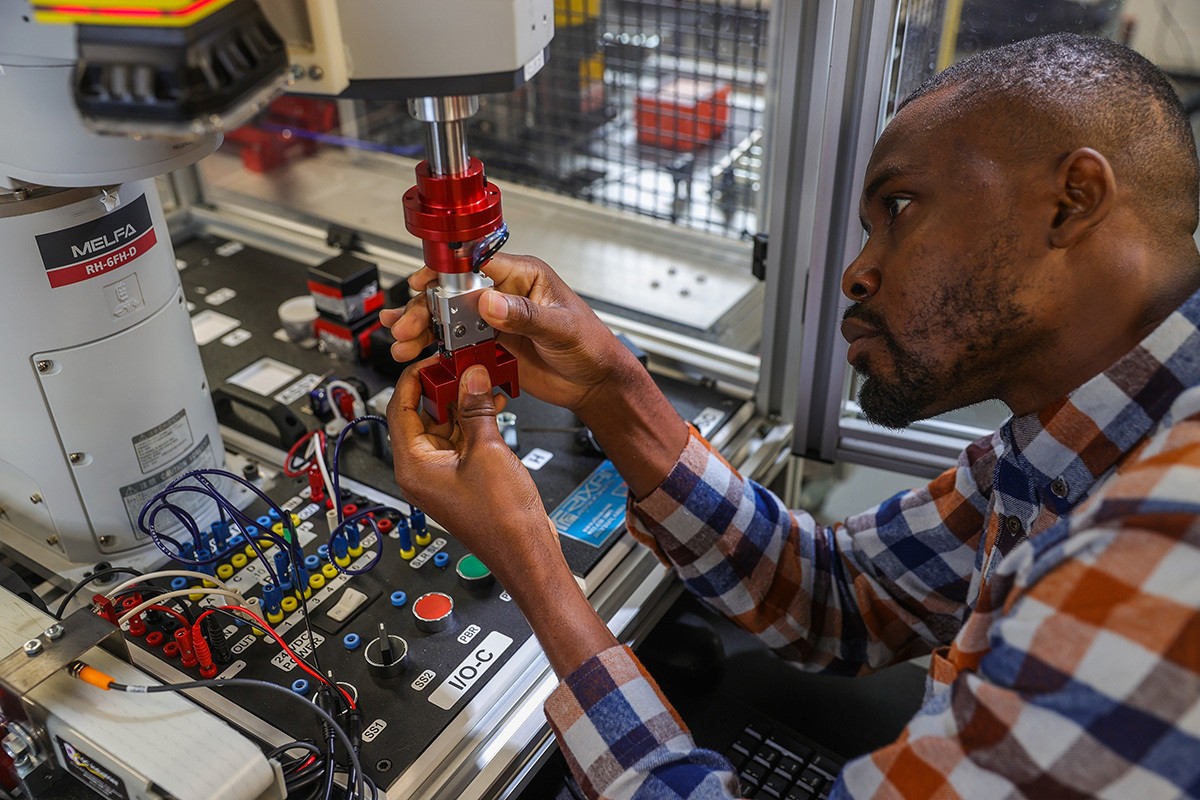

The facilities in the School of Engineering are places to learn – and spaces designed to spark creativity and foster collaboration.

- Students work with the tools and technologies they will encounter in their careers.

- Faculty and students partner with industry leaders on research, prototyping and workforce development.

Opening in spring 2026, the School of Engineering’s newly expanded home on campus will provide our undergraduate and graduate students with 62,000 square feet of:

- Ultra-modern classrooms

- Fresh collaboration areas

- Specialized labs with flexible spaces to support high-tech equipment, tools and innovative learning

Updated: 02/06/2026 04:28PM