BGSU helps regional manufacturers adapt to advances in smart manufacturing through microcredential training program

Estimated Reading Time:

The federally-funded program upskills the current manufacturing workforce through self-paced, personalized learning

By Laren Kowalczyk ‘07

As a public university located in the nation's manufacturing heartland, Bowling Green State University is developing a microcredential training program to help regional manufacturers advance in smart manufacturing.

The program, Advancing Regional Talent in Smart Technology Enabled Manufacturing, upskills the current manufacturing workforce and builds a pipeline of high school and community college students interested in pursuing careers in science, technology, engineering and math (STEM).

The University was among 11 recipients nationwide and the only in Ohio to receive a $333,000 grant from the U.S. Economic Development Administration’s 2023 STEM Talent Challenge.

The national competition supports programs to advance careers STEM fields.

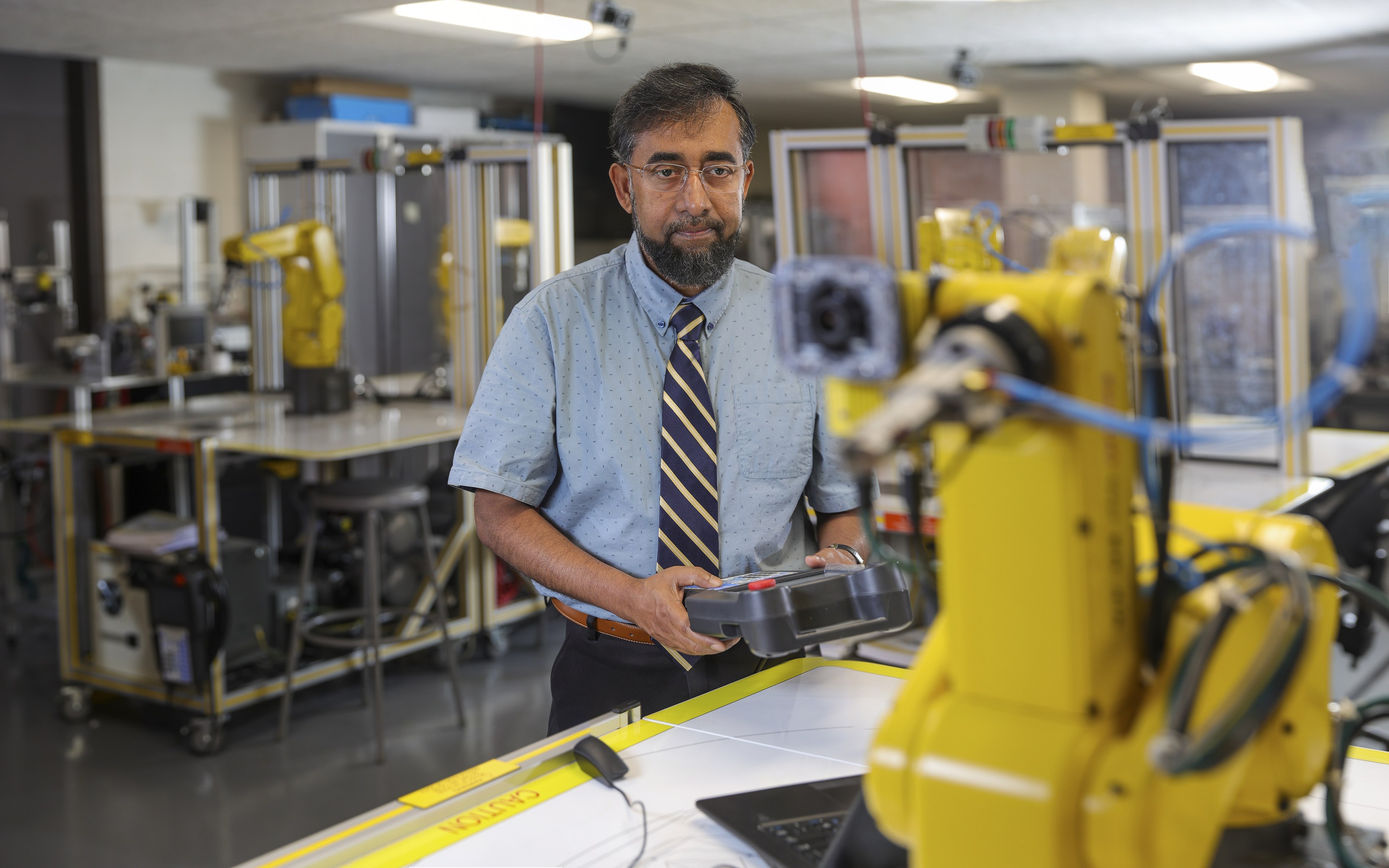

“Meeting workforce demands is a crucial part of our mission as a public university for the public good,” said Dr. MD Sarder, director of the BGSU School of Engineering, who is leading the project. “The training available through this program will be customized to align with the needs of manufacturers in our region, helping them build and retain a qualified workforce.”

An additional goal of the program is to increase representation of minoritized groups within smart manufacturing. Sarder said BGSU undergraduate students will have access to the training in future project phases.

Far-reaching impact

Sarder plans to recruit the next generation of engineers and robotics professionals by leveraging relationships he has built with local high schools and community colleges through an existing grant from the National Science Foundation.

For the workforce training portion of the grant, Sarder is collaborating with the Center to Advance Manufacturing – a collaboration between BGSU, the University of Findlay and Owens Community College – and the Center for Regional Development to identify specific industry needs, develop curriculum and recruit professionals interested in advancing their careers.

Tim Mayle, executive director of the Center to Advance Manufacturing, said the training program's impact will be far-reaching as one in five people who live in the counties along the I-75 corridor in northwestern Ohio work in manufacturing. The counties east and west of the interstate rely even more heavily on manufacturing for their livelihood.

“Manufacturing technology is advancing at an incredible pace. As companies continue to innovate and adopt new technology, their workforce must acquire new skills,” Mayle said. “Through this grant, we’re helping to bridge that workforce skills gap by providing employees with the knowledge needed to thrive in smart manufacturing.”

Workforce training ecosystem

The EDA grant funds the development of 16 non-credit training modules as part of what Sarder calls the smart manufacturing workforce training ecosystem.

Participants can follow tracks in either robotics and automation or smart manufacturing, with modules focused on industrial sensors and actuators, artificial intelligence and machine learning, additive manufacturing, quality control and lean practices.

Learning units are stacked into small modules that support skill development through the presentation of theory, which is reinforced through hands-on application.

The modular system promotes data-driven personalized learning by using the participant’s background, possessed skills and desired learning to formulate a customized list of modules to complete.

Although individual modules are not completed for academic credit, Sarder said they can be stacked together into credit-earning systems.

The self-paced online, in-person and hybrid courses range from one to three weeks and will be taught by BGSU engineering faculty. The experiential learning portion of the training will be held at the eFactory inside the Stephen and Deborah Harris/RIXAN Robotics Laboratory on the BGSU campus.

“Manufacturing in Ohio and across the country is changing rapidly because of technological advances,” Sarder said. “To support those changes, we need to retool our workforce. This program is one part of solving that problem.”

BGSU is further supporting industry needs through three new fully-accredited academic programs, including robotics engineering, electronic and computer engineering, and mechanical and manufacturing that cater to the expanding field of advanced manufacturing and technological innovation, offering a unique blend of science and engineering application that employers say is needed in the current and future industry landscape.

Related Stories

Media Contact | Michael Bratton | mbratto@bgsu.edu | 419-372-6349

Updated: 03/14/2024 02:02PM